Flap Wheel Manufacturers in India

Being an established Flap Wheel Manufacturers in India, we use quality flap wheels, which are suitable in providing consistent performance, life and consistent surface results.

We make our flap wheels using high quality abrasive flaps that are positioned around a robust core to offer even and smooth contact with the work surface. Such design gives flexibility of grinding action, minimized vibration and controllability unlike the traditional grinding wheels. Our flap wheels are suitable to use on metal, stainless metal, wood and non-ferrous materials to facilitate both precision finishing and the general surface preparation work.

The flaps have been designed so that every flap wheel is balanced and efficient in cutting during the service lifetime. Quality testing guarantees consistent bonding, performance of the abrasive and safe operation at the recommended speeds. Our flap wheels are constructed to resist heat and friction as well as consistent operation which provides reliable performance in harsh industrial and workshop conditions.

Flap Wheel Suppliers in India : Trusted Supply Chain

Being reliable Flap Wheel Suppliers in India, we will assure a consistent supply of products to workshops, fabrication units and industrial buyers. The good supply network that we have enables us to deliver the flap wheels efficiently and with safe packaging and quality standards of the same.

Our services involve helping customers to make the correct choice on the type of flap wheel to use depending on the type of material, grit size and use. You need a small amount or a large-volume supply, we are concerned with punctual delivery, low prices, and reliable services. The focus of our supplier strategy is based on long-term relationships and consumer satisfaction.

Flap Wheel Dealers in India: Simple Entry and Pro Profession.

We have Flap Wheel Dealers in India, offering them easy access to the actual products and professional advice. Dealers know the applications of finishing and surface preparation and assist users in selection of the appropriate flap wheel in the event of grinding, polishing or blending.

Customers get genuine products, technical support, and after sales through our dealer network. Timely availability and guidance in the application is a guarantee of an efficient and easy finishing process.

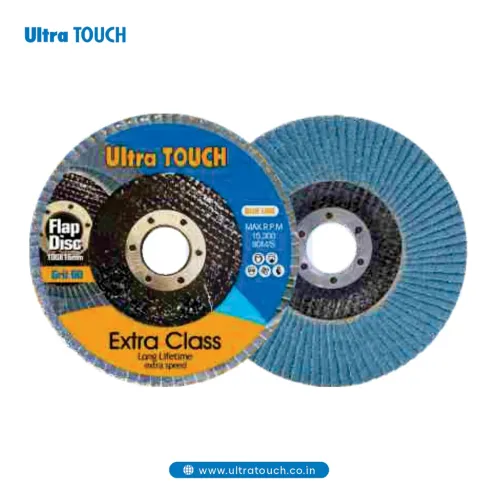

| FLAP WHEEL – TECHNICAL SPECIFICATIONS | |

|---|---|

| Parameter | Specification |

| Product Name | Flap Wheel |

| Type / Variants | Flexible Flap Wheel, Blue Series Flap Wheel, Metal Cap Flap Wheel, Standard Flap Wheel, Fibre Disc |

| Brand / Series | Ultra Touch |

| Disc Diameter | 4″, 5″, 7″ |

| Grit Sizes Available | 24, 36, 60, 80, 100, 120, 220, 320 |

| Abrasive Material | Premium Aluminum Oxide |

| Backing Material | Fiberglass / Metal Cap (as applicable) |

| Wheel Structure | Overlapping abrasive flaps bonded to backing |

| Center Hole | Standard grinder arbor (22.23 mm) |

| Operating Speed | Suitable for standard angle grinders |

| Finish Type | Coarse grinding to fine finishing |

| Application | Grinding, blending, deburring, surface finishing |

| Suitable Materials | Mild steel, stainless steel, alloy steel, metal surfaces |

| Usage | Professional & industrial use |

| Mounting Type | Angle grinder mounting |

| Performance | Smooth operation with reduced vibration |

| Durability | Long service life with consistent cutting performance |

Flap Wheel Wholesalers in India: Bulk Supply Solutions

We also partner with trusted Flap Wheel Wholesalers in India to take the form of bulk orders to satisfy the needs of retailers, distributors, and industrial purchasers. The wholesale partners receive the advantage of having steady stock supply, favorable prices and high-quality logistics services.

Our network of wholesalers has facilitated uninterrupted supply of products and has helped businesses to grow by giving them efficient order taking and order delivery.

Applications of Flap Wheels

Flap wheels have many applications in a range of surface finishing and preparation operations, including:

- Welded joints Smoothing and blending.

- Metal and stainless steel finishing.

- Eliminating burrs, rust and surface defects.

- Cleaning of surfaces prior to painting or coating.

- Woods, plastic materials as well as non-ferrous.

Flap wheels are perfect to give clean and uniform finishes due to their flexibility and smooth abrasive finishing.

Why Choose Our Flap Wheels

Our flap wheels will be that of controlled material removal, smooth finishes, and long life cycle. The flap is flexible to contours of the surfaces, thus preventing gouging and enhancing finish quality. Balanced construction is the one that can guarantee stable operation with low vibrations.

We are also value and usability oriented. The flap wheels are interchangeable with any standard grinders and finishing tools, and they are therefore simple to incorporate into the current work processes. With the help of a powerful system of suppliers, dealers, and wholesalers, our flap wheels provide an effective availability and professional assistance when required.

Contact Us Your Flap Wheel friend

Our flap wheels will be of top quality, safety, and performance. Through collaboration with the reputable manufacturers and distributors, we deliver products that allow professionals to produce the same and efficient finishing results.

Call us today and we will be happy to discuss our full line of flap wheels and provide you with the necessary guidance on the one that you need. Our flap wheel solutions can assist you to ensure high standards of surface quality, productivity, and finishing efficiency.

In contrast to grinding wheels, flap wheels result in more gentle finishing along with less heat generation. They slowly consume fresh abrasive, thus allowing better control and more even results, particularly on rounded or sensitive surfaces.

A flap wheel is generally employed in a range of operations such as grinding, blending, deburring, and surface finishing. Besides smoothing welds, removing rust, and preparing surfaces, the tool is also capable of metal fabrication and finishing since it doesn't harm the base material.

Low grit flap wheel can strip the material fast while high grit ones are capable to provide smooth finishing. The right grit to choose should be determined by the kind of work you have - heavy grinding, surface blending or final polishing for the desired finish.