Grinding Wheel Manufacturers in India

We've been leading Grinding Wheel Manufacturers in India, so we know how to make them good. They work well, last long, and are safe to use, even when things get tough.

As top grinding wheel makers in India, we’re experts at producing quality wheels. These grinding wheels last. They work great, even when things get tough. Plus, they're safe because we only use the best stuff to make them.

This makes sure they cut smoothly and last. Every wheel is balanced to reduce vibration and give steady results over time. Both hand-held and machine operations are made easy by the accuracy, reliability, and speed of our wheels.

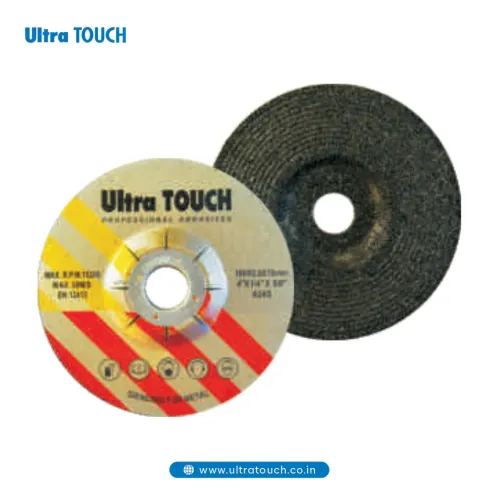

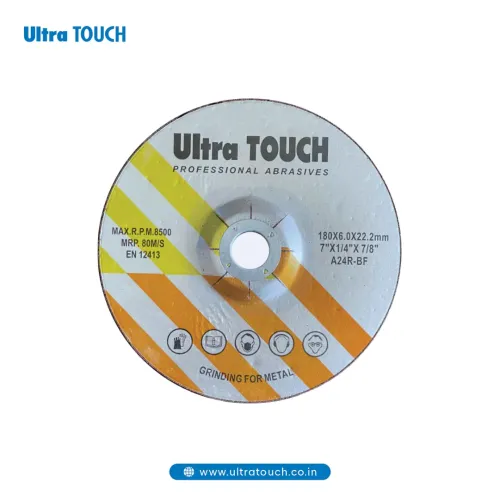

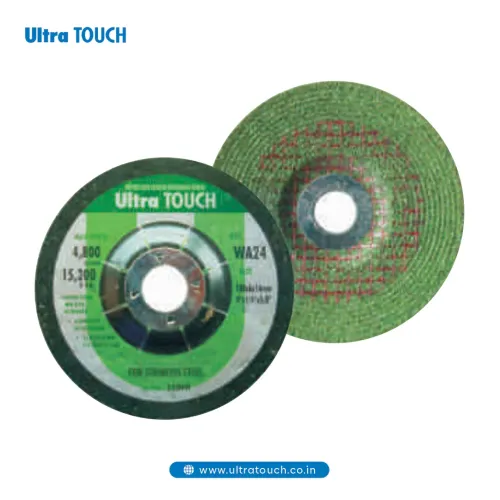

We supply all kinds of grinding wheels to keep up with the difference between shops and factories. Each wheel goes through testing to ensure top strength, cutting power, and safety before it ships. Our grinding wheels work great if you need to remove stuff or smooth things out. They even work when you crank up the speed. They can take the heat and won't fall apart, even if you use them a lot.

Grinding Wheel Suppliers in India : Consistent Quality Supply

As dependable Grinding Wheels Suppliers in India, and with consistent service for the large and small workshop types and Fabrication Units, we have developed a strong distribution network that enables us to provide a continuous supply of our products, while maintaining high-quality and secure packaging.

In addition to providing our Customers with a continued consistent supply of Grinding Wheels, we also provide support with selecting the most suitable Grinding Wheel, based on the materials type, hardness of the material, application of the grinding process, and type of Grinding Machine used in conjunction with our Grinding Wheels.

Whether you need a standard-size wheel or a large quantity of wheels, we will deliver your choices promptly and competitively priced with a commitment to providing reliable service. As a result, we focus on developing long-term relationships with our clients and have become their preferred supplier for many industries.

Grinding Wheel Dealers in India : Trusted Local Support

We are authorized Grinding Wheel Dealers in India and make it easy for customers to purchase authentic products and receive expert advice on the various types of Grinding Wheels available. Dealers are also very knowledgeable regarding the many different applications of Grinding Wheels, and can assist their customers in selecting the proper Grinding Wheels for their needs in completing Metal Grinding, Surface Finishing, Deburring or Sharpening Tasks.

When customers purchase from our authorized dealer network, they receive assurance of product authenticity, guidance on the proper use of the product and quick delivery. In addition, our dealers can offer their customers valuable assistance with respect to product application and after-sales support; thus providing customers with an optimal grinding operation.

This strong dealer presence allows us to reach customers quickly and provide reliable local support.

| TECHNICAL SPECIFICATIONS | |

|---|---|

| Parameter | Details |

| Product Name | Grinding Wheel |

| Brand | Ultra Touch |

| Voltage / Frequency | 220 V / 50 Hz |

| Input Power | 1050 W |

| No Load Speed | 11,000 RPM |

| Wheel Diameter | 100 mm |

| Spindle Thread | M10 |

| Switch Type | Slide Switch |

| Body Material | High-Grade Plastic |

| Motor Type | Heavy-Duty Copper Motor |

| Insulation Class | Double Insulation |

| Usage Type | Industrial / Professional |

| Application | Cutting, Grinding, Polishing |

| Compatible Accessories | Grinding Wheel, Cutting Wheel, Flap Wheel |

| Country of Origin | India |

Grinding Wheel Wholesalers in India : Bulk & Industrial Supply

We have partnered with trusted Grinding Wheel Wholesalers in India to help retailers, distributors and industrial buyers fill their bulk capacity requirements. By creating partnerships with dedicated wholesale partners across India we are able to deliver a consistent supply of product at competitive pricing with dependable shipping and logistics support to our partners which enables them to continue fulfilling their customers' needs without interruption.

In addition to providing wholesale partners with an uninterrupted supply of Inventory and Packaging and Shipping support, our wholesale systems are designed to assist wholesale partners in managing their own Inventories efficiently.

This strengthens the supply chain and ensures grinding wheels are readily available wherever needed.

Applications of Grinding Wheels

Grinding wheels are widely used across multiple industries for various surface preparation and material removal tasks, including:

- Grinding metal surfaces for smooth finishing

- Removing excess material from welded joints

- Sharpening cutting tools and machine components

- Deburring edges and cleaning rough surfaces

- Grinding wheels are super useful when you're getting parts ready for paint, coatings, or putting stuff together.

You'll find them all over the place – from metal shops to car garages, building sites, and even maintenance crews can use them.

Why Choose Our Grinding Wheels

Designed for optimally achieving high quality finished ground surfaces with good repeatable results over extended periods of time; they reduce vibrations enabling users to successively achieve accuracy and consistent work during tough Heavy duty applications. Strong bonding plus a balanced construction contribute to increased safety and improved productivity.

We also focus on user confidence and value. Our grinding wheels fit right onto your regular grinders and angle grinders, so you can start using them without any hassle.

Supported by a strong supply, dealer, and wholesale network, our products ensure dependable availability and professional support whenever required.

Get in Touch – Your Grinding Wheel Partner

Our customers' grinding wheel, which is a high-quality and continuous-flowing product, can be used to perform grinding operations more effectively. In partnering with reputable manufacturers and distributors, we are excited to provide our customers with the best mix of Safe Products, Product Performance, and Quality. This will create a Sustainable Source of Quality Products for our customers.

In addition, because we have the industry knowledge and experience, we can assist you in selecting the most appropriate Grinding Wheel for your application. If you would like to improve the Surface Finish of your Parts, while at the same time decreasing Material Removal Time, please give us a call today so we can guide you through this process.

Lower grit takes off stuff quickly but if you want it smooth, go high. Pick what fits how you need it done.

The reason for the very fast wear is that too much pressure has been used or that the wheel is not suitable for the material to be ground. Only make the wheel work and be sure that it is the right one for the job.

A wheel that is perfect for steel may not be capable of cutting stone or softer metals. The right wheel for each material will bring you better results, and the tool will remain safe.