Saw Blade Manufacturers in India

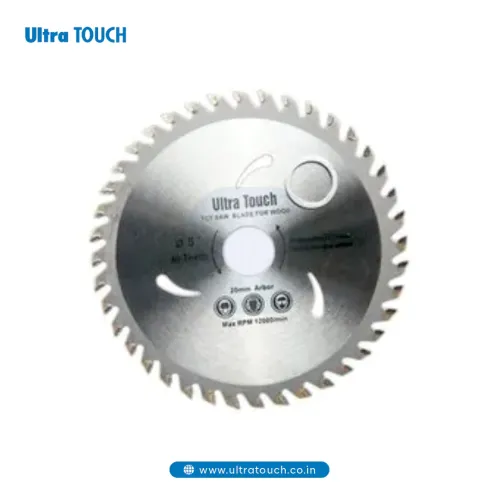

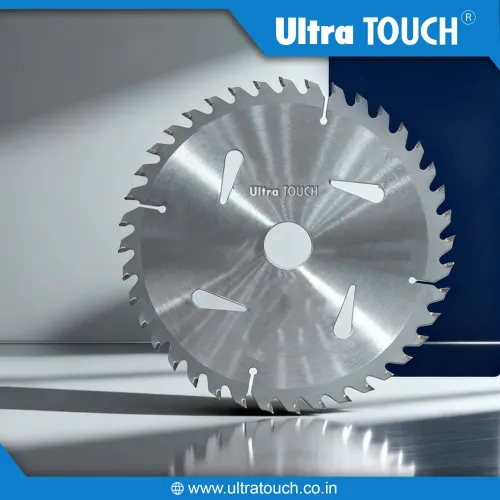

Saw blades are the cutting tools used with precision to provide clean, accurate and efficient cuts on a variety of materials. Since the art of woodworking and metal fabrication up to construction and industrial processing, the importance of the saw blades in maintaining the same cutting effect is vital. We are the experienced Saw Blade Manufacturers in India and we prepare quality blades which are made in the major features of strength, sharpness, and durability of working in harsh conditions.

Our saw blades are also produced with grade steel and superior tooth configurations to provide easy cutting, minimized vibration, and blade life. The blades are strong enough to ensure that they cut on point and that the material is not wasted or the heat generated is limited. Our saw blades can be used with all types of circular saws, table saws, and cutting machines, and they can be used with ease regardless of the intent of their use, either in professional or industrial settings.

Each saw blade has been specifically developed to high quality and safety standards. Strict testing maintains a balance of blades, tooth hardness and cutting efficiency of products prior to delivery. Our saw blades are also reliable in continuous operation regardless of whether they are doing high-speed cutting or precision finishing. Their robust construction enables them to carry heavy loads but with persistence.

Saw Blades Suppliers in India: Dependable Supply Chain

Being reputed Saw Blade Suppliers in India, we are in a position to supply saw blades to the workshops, manufacturing plants, retailers and the large construction projects sites in India at all times. Instead, our well-developed supply chain enables us to provide products with an effective delivery system that is well packaged and has reliable logistics.

We help the customers to pick the correct saw blade depending on the material type, cutting purpose, blade size, and tooth structure. You are required to use blades on wood, metal, plastic, or composite material, we can help you out to achieve the best cutting results. Between individual orders to bulk supply, we concentrate on competitive prices, timely delivery and effective service. Our supplier strategy is founded on long-term cooperation and clientele satisfaction.

Saw Blade Dealers in India: No Fuss and No Rush

The presence of our licensed Saw Blade Dealers in India also enables the customers to find authentic products and professional guidance at their convenience. Dealers know all the types of cutting applications and can assist the users to find the best blade to use in certain machines and materials.

We have a dealer network that enables our customers to experience original products supported by the manufacturer, usage, and warranty services. The availability of spare blades, accessories and technical support makes the cutting operations continue smoothly. Such a good dealer network will enable us to deliver prompt accessibility and reliable services in various regions.

| SAW BLADE – TECHNICAL SPECIFICATIONS | |

|---|---|

| Specification | Details / Typical Values |

| Product Name | Saw Blade |

| Material | High-Speed Steel (HSS), Tungsten Carbide Tipped (TCT), Carbon Steel |

| Blade Type | Circular Saw Blade / Band Saw Blade / Hand Saw Blade |

| Diameter / Length | Circular: 100 mm – 400 mm |

| Band Saw: 1,500 mm – 5,000 mm | |

| Thickness | 1 mm – 5 mm |

| Bore Size / Arbor Hole | 10 mm – 32 mm |

| Teeth per Inch (TPI) | 24 – 120 TPI (low TPI for rough cuts, high TPI for fine cuts) |

| Tooth Type / Geometry | ATB (Alternate Top Bevel), TCG (Triple Chip Grind), FTG (Flat Top Grind), Hook Angle |

| Recommended Speed | 3,000 – 6,000 RPM (depending on blade type and material) |

| Applications | Wood, Metal, Plastic, Laminates, Aluminum, MDF |

| Coating / Finish | Titanium Nitride (TiN), PTFE, or Black Oxide for durability and reduced friction |

| Durability / Life | Long-lasting when used with correct RPM, feed rate, and material type |

| Safety Notes | Wear protective eyewear and gloves; ensure proper mounting before operation |

Saws Blades Wholesalers in India Bulk Supply Solutions

To fulfill bulk orders to the retailers, distributors and industrial purchasers, we make agreements with trusted Saw Blade Wholesalers in India. The advantages of our wholesale partners are the availability of stocks at any time, competitive prices, and controlling inventory.

Our wholesale supply system offers uninterrupted supply of saw blades with streamlined ordering procedures, safe packaging, and timely delivery in the market. This consolidates the entire supply chain and assists the partners in fulfilling the increasing market demand and at the same time, maintaining the same quality.

Applications of Saw Blades

The saw blades are common in various industries and cutting applications, such as:

- Sawing wood, plywood and board laminations.

- Fabrication and manufacturing metal cutting.

- Cutting composite materials, PVC and plastic.

- Infrastructure and construction excavation.

- Furniture industry and interior finishing.

Saw blades are important tools because of their versatility and accuracy in workshops, factories and construction sites.

Why Choose Our Saw Blades

Our saw blades are made in such a way that they provide us with accurate cuts, finish, and long life. A high quality and advanced tooth design assists in minimizing cutting resistance, possessing a lower vibration rate, and enhancing the efficiency. This leads to clean cuts, shorter operation time and wear on cutting machines.

Safety and reliability are also of concern to us. The design of balanced blades provides balanced rotary speed at high speed avoiding fatigue to the operator and enhances control. We have a very broad compatibility with saw blades to a large number of cutting machines and can be easily incorporated into the current workflows. Our products have a good network of suppliers, dealers, and wholesalers who have guaranteed reliable supply and professional assistance in case of need.

Get in Touch With Your Saw Blade Partner

We have the obligation to provide saw blades of a high standard of quality, safety, and performance. We provide precision and accuracy in all applications by cooperating with reliable manufacturing and distribution partners to provide cutting solutions to promote efficiency.

Call us today and check out our entire line of saw blades and have the knowledge of which blade fits your requirements. Our saw blade solutions will ensure that you get cleaner cuts, better productivity and consistent results.

The appropriate saw blade is reliant on the material that you are cutting, the blade size, and tooth design. Wood, metal, and plastic need different blades. By simply picking the right blade you not only get cleaner cuts but also put less strain on your tool.

Overheating is mainly caused by a dull blade, wrong blade type, or too fast cutting. Inserting a sharp blade and letting the tool do the job at a uniform pace will enable you to avoid heat buildup and will also enhance the cutting performance.

If you want to have your blade for a longer time, then you should keep it clean, not force the cut, and use the correct blade for the material. Besides the right storage, checking it regularly will also help to prevent the blade from being damaged and keep it accurate.