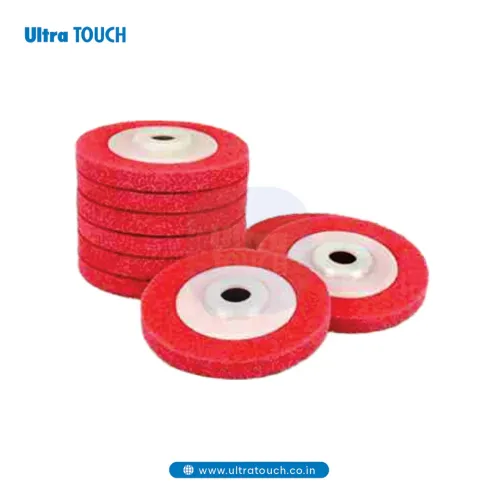

Polishing Wheel Manufacturers in India

Polishing wheels are finishing tools that are indispensable in producing smooth, glossy and refined surfaces to a very wide variety of materials. They are widely applied in the field of metalworking, vehicles, fabrication, and finishing to improve the surface quality and minimize minor flaws. Being established as Polishing Wheel Manufacturers in India we manufacture quality polishing wheels that would deliver the same performance, durability, and excellent finishing outcomes.

The materials we use to make our polishing wheels are of high quality like cotton, felt and some special polishing fabrics which are guaranteed of soft, but effective treatment of the surface. These wheels are made to be used effectively with polishing compounds and assist in producing a smooth finish and allow control and precision. Our polishing wheels can be used on metals, stainless steel, aluminum, and other surfaces; they are suitable in the industry and workshop finishing.

The polishing wheels are also designed to balance and spin smoothly reducing vibrations and making them safe. Strict quality tests are used to assure strength and durability as well as the uniformity of polishing performance. Our polishing wheels are designed to resist heat, friction, and constant usage, which means that we can equip our polishing wheels with reliable results even in the cases when the process of polishing lasts a long time.

Polishing Wheel Suppliers in India : Supply Solutions

Being the reliable Polishing Wheel Suppliers in India, we maintain the constant supply of polishing wheels to the workshops, fabrication plants and industrial consumers. We have an excellent supply network that provides delivery in time and safe packaging, as well as stable quality of our product.

We help the customer to choose the suitable polishing wheel depending on the type of material, and finishing need, compatibility of polishing compound. It does not matter whether you are ordering small quantities or a bulk order but with a competitive price offered, fast delivery and reliable service. Our supplier strategy is based on long-term partnership and client satisfaction.

Polishing Wheel Dealers in India : Local Support and Expertise

We have Polishing Wheel Dealers in India who are authorized which makes it easy to get real products and professional advice. Dealers know how to use a variety of surface finishing and assist customers in selecting the best polishing wheel to use in buffing, shining or final finishing.

Our customers get access to genuine products, application support, and after sales services through our network of dealers. The availability of the polishing is done smoothly and efficiently by the availability of quick and expert guidance.

| POLISHING WHEEL – TECHNICAL SPECIFICATIONS | |

|---|---|

| Specification | Details / Typical Values |

| Product Name | Polishing Wheel |

| Material | Cotton, Wool, Felt, Sisal, or Combination |

| Shape | Flat, Cylindrical, or Buffing Wheel |

| Diameter | 50 mm – 300 mm (depending on machine/application) |

| Thickness / Width | 10 mm – 50 mm |

| Bore Size | 6 mm – 32 mm (center hole for mounting on spindle) |

| Grit / Finish Type | Fine, Medium, or Coarse (depending on polishing compound) |

| Speed Limit | 2000 – 6000 RPM (depends on material and mounting) |

| Application | Metal, Wood, Plastic, Jewelry, Stone, Automotive finishing |

| Mounting Type | Spindle-mounted or Arbor-mounted |

| Compound Used | Polishing compounds like rouge, aluminum oxide, or diamond paste |

| Durability | Long-lasting if used with correct speed and compound |

| Safety Notes | Use protective eyewear and gloves; ensure wheel is properly mounted before operation |

Polishing Wheel Wholesalers in India: Bulk Supply Support

We have partnerships with trusted Polishing Wheel Wholesalers in India to satisfy bulk supply needs of retailers, distributors and industrial purchasers. Our wholesalers enjoy consistent supply of stocks, reduced prices and effective management of their logistics.

Our wholesale supply system gives continuous supply of products at the right time, with the simple order processing and shipment, ensuring the growth of business.

Applications of Polishing Wheels

Applications Polishing wheels from a wide range of finishing applications include:

- Metallic and Stainless steel polishing.

- Polishing car parts and industrial parts.

- Eliminating superficial scratches and marks.

- Improving the lustre of aluminum and brass components.

- Last surface finishing preceding inspection or delivery.

- Polishing wheels are also necessary because of their capabilities to provide smooth and glossy finishes to surfaces in treating them in high quality.

Why Polishing Wheels: Our Polishing Wheels

We have designed our polishing wheels to provide uniform shine, smooth operation and long life. Balanced construction and carefully chosen materials allow the achievement of the same polishing results and minimization of vibration and heat accumulation.

We are also concerned with convenience and price. The polishing wheels can be used with ordinary polishing machines and grinders and thus are applicable in a variety of tasks. Our polishing wheels are backed by a good network of suppliers, dealers and wholesalers meaning that they are available when needed and can provide professional assistance.

Get in Touch With Your Polishing Wheel Partner

We will provide polishing wheels that are of high quality, safety and performance. Through collaboration with reputable manufacturing and distribution partners, we can provide products that will enable professionals to get high-quality surface finish with confidence.

Call us and find out about our entire line of polishing wheels and have our professionals help you to choose the proper solution to your problem. Our trusted polishing wheel products will assist you to improve the quality of surfaces, productivity, and finishing efficiency.

No, not really. Every material requires a different polishing wheel and a different polishing compound. In case of the right combination of materials, the metal surface will not be burnt and the result will be better if it is stainless steel, aluminum, brass, or any other metal.

A polishing wheel is basically the one that brings the smoothness, the shine and most of all the finish of the metal/plastic or any other material workpiece after grinding or sanding the surface. It basically eliminates scratches of very small size and makes the metal or plastic look like a bright, shiny and clean one.

Polishing the wheel always, not pressing too hard, and using the correct polishing compound are some ways of extending the life of the polishing wheel. If the wheel is kept stored in a dry place and is dressed from time to time, it will remain in good condition and will still be able to polish effectively after a long time.