Flap Wheel Manufacturers in Jamshedpur

Flap wheels are an important abrasive tool which are used to finish, blend, and light grind or polish the surface in various sectors. They have been developed to produce smooth, uniform finishes and have been able to control and work on contours better than traditional grinding wheels. They can easily be shaped to the contours of the surfaces and hence are suitable in accurate-finishing as well as in general surface preparations.

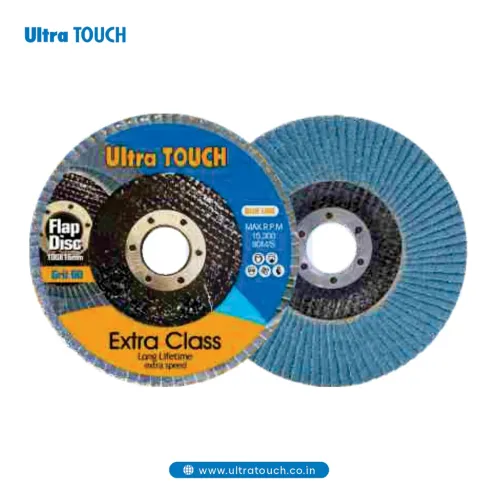

As a well established Flap Wheel Manufacturers in Jamshedpur we are able to produce high quality flap wheels that have similar performance, are strong in operation and will have reliable surface results. Our flap wheels are made by taking high quality abrasive flaps that are well placed to form a strong and durable core. This construction gives the work surface a clean and smooth grinding action that has less vibration and better control. Our flap wheels are flexible in comparison to the rigid grinding wheels and hence they are able to finish better without damaging the material.

Our flap wheels can be applied to metal, stainless steel, wood, and non-ferrous material, and thus can be used in a variety of workshops and industrial applications. It is either fine finishing, blending, or cleaning the surface, either way, our products are efficient in a host of tasks. The design of every flap wheel ensures that it performs well, and its cutting ability is consistent throughout its service life.

Flap Wheel Suppliers in Jamshedpur – Reliable Supply Chain

Being the reputable Flap Wheel Suppliers in Jamshedpur we guarantee continuous and consistent supply of flap wheels to the workshops, fabrication units and the industrial purchasers. We have a well-developed system of supply, which helps us to introduce products into the market rather quickly and keep the same high quality and safe packaging.

We help in guiding the customers to choose the appropriate flap wheel according to the type of material, the size of the grits, and the application needs. You require a small amount to use in the workshop or large quantities needed in an industrial project. We are concerned with timely delivery, good prices and reliable service. We develop our supplier strategy based on long-term relations, which allows our clients to continue with the running of operations and stable performance.

Flap Wheel Dealers in Jamshedpur - Fast and Direct Access and Expert Advice

Our authorized Flap Wheel Dealers in Jamshedpur help us make genuine products easily accessible and offer professional advice. Our dealers know how to use surface finishing and preparation applications and guide customers on the most appropriate flap wheel to use in the surface finishing, polishing, blending, or cleaning job.

Customers get original products through our dealer network that has technical support and after sales services. Timely access and professional advice will guarantee effective completion of work, less downtime, and work quality. This dealer support solution provides more confidence to the user, and long-term performance is guaranteed.

| FLAP WHEEL – TECHNICAL SPECIFICATIONS | |

|---|---|

| Parameter | Specification |

| Product Name | Flap Wheel |

| Type / Variants | Flexible Flap Wheel, Blue Series Flap Wheel, Metal Cap Flap Wheel, Standard Flap Wheel, Fibre Disc |

| Brand / Series | Ultra Touch |

| Disc Diameter | 4″, 5″, 7″ |

| Grit Sizes Available | 24, 36, 60, 80, 100, 120, 220, 320 |

| Abrasive Material | Premium Aluminum Oxide |

| Backing Material | Fiberglass / Metal Cap (as applicable) |

| Wheel Structure | Overlapping abrasive flaps bonded to backing |

| Center Hole | Standard grinder arbor (22.23 mm) |

| Operating Speed | Suitable for standard angle grinders |

| Finish Type | Coarse grinding to fine finishing |

| Application | Grinding, blending, deburring, surface finishing |

| Suitable Materials | Mild steel, stainless steel, alloy steel, metal surfaces |

| Usage | Professional & industrial use |

| Mounting Type | Angle grinder mounting |

| Performance | Smooth operation with reduced vibration |

| Durability | Long service life with consistent cutting performance |

Flap Wheel Wholesalers in Jamshedpur - Bulk Supply Solutions

We also work with reputable Flap Wheel Wholesalers in Jamshedpur to fulfill the bulk needs of retailers, distributors and large industrial customers. Our wholesale customers enjoy steady supply of stock, good prices and advanced logistics assistance.

The efficient system of supplying the market by the use of a smooth ordering schedule and a quick delivery system ensures that wholesalers do not experience any lapses in supply and meet the demand in the market effectively. This is an effective wholesale network, which facilitates growth in the business and the availability of flap wheels in various regions.

Applications of Flap Wheels

The flap wheels are used in several surface finishing and preparation jobs; such as:

- Welding of joints and their smoothing and blending.

- Metal and stainless steel finishing.

- Elimination of burrs, rust, paint, and surface defects.

- Cleaning of the surfaces before painting or coating.

- Wood, plastic and non-ferrous finishing.

They can be used both in industries and workshops due to their versatile abrasive structure that can be uniformly removed and provides clean and smooth finishes, resulting in smooth and clean cuts.

Why Choose Our Flap Wheels

- Our flap wheels will have controlled material removal, finishes and long service life.

- The flap is flexible and fits the surface contours minimizing the possibility of gouging and improving the quality of finish.

- Balanced construction guarantees stable functioning with low vibration, enhancing security, and comfort of the user.

- Our specialization is also convenient with the price.

- Our flap wheels can be used with regular grinder and finishing tools, and can be easily integrated with existing processes.

- Our products have a very good supply chain consisting of suppliers, dealers, and wholesalers who can help us to get the products whenever we need them.

Contact Us Your Flap Wheel Partner

Our mission is to produce flap wheels of high quality, safety and performance. We deliver abrasive solutions through the cooperation with trusted manufacturing and distribution partners to assist the professionals to obtain efficient and consistent finishing outcomes.

Today, contact us and we will discuss the full selection of flap wheels and provide you with the best advice on the correct product to use in your application.

Allow our flap wheel solutions to assist you in enhancing the quality of surfaces, productivity, and reliability in the finish performance of every job.

In contrast to grinding wheels, flap wheels result in more gentle finishing along with less heat generation. They slowly consume fresh abrasive, thus allowing better control and more even results, particularly on rounded or sensitive surfaces.

A flap wheel is generally employed in a range of operations such as grinding, blending, deburring, and surface finishing. Besides smoothing welds, removing rust, and preparing surfaces, the tool is also capable of metal fabrication and finishing since it doesn't harm the base material.

Low grit flap wheel can strip the material fast while high grit ones are capable to provide smooth finishing. The right grit to choose should be determined by the kind of work you have - heavy grinding, surface blending or final polishing for the desired finish.