Angle Grinder Manufacturers in Bihar

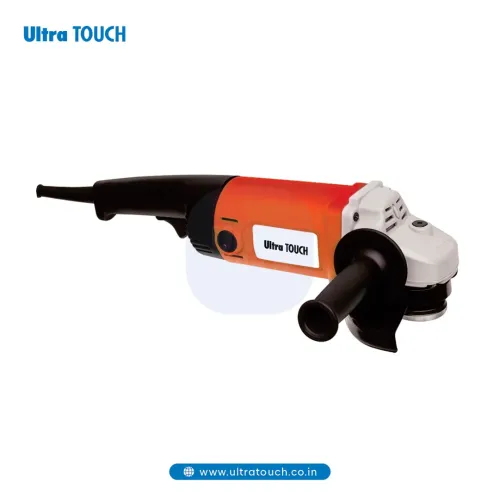

Angle Grinders in Bihar redefine performance, durability and safety among power tool users in the profession. Unlike many other tools, which are designed to satisfy the increased need of fabrication, construction and maintenance industries, these tools provide high speed grinding, cutting and polishing with a constant degree of accuracy. Every angle grinder is designed with a stable motor balance and endearing inner parts so that they would remain stable even when they are in use over a long period.

Constructed to serve an industrial or a workshop use, angle grinders provide powerful production with good control. High technology in motor technology guarantees smooth operation and the ergonomic design that minimizes operator fatigue. These grinders can be used in cutting metals, surface finishing, or material finishing and in all cases, they offer reliable results.

Being reliable Angle Grinder Manufacturers in Bihar, we specialize in manufacturing tools that have strength, safety and extended service life. All the units are evaluated in terms of stability in speed, torque and operational safety so that they can work effectively in rigorous working conditions.

Features of Angle Grinders

- RPM motors are highly faster and efficient cutters.

- Structures of continuous heavy duty.

- Gallant housing of vibration and impact resistance.

- Better handling, more comfortable ergonomic grip.

- Combined safety protective measures of operators.

- Industrial, commercial and workshop.

Reliable Angle Grinder Suppliers in Bihar : Premium Power Tool Network

We are credible Angle Grinder Suppliers in Bihar whereby we guarantee the availability of quality power tools throughout the workshops, retailers, and industrial units. By the use of our integrated supply chain, it is easy to move goods in urban and semi-industrial areas quickly without wastage of time.

Each angle grinder will be well packed to prevent damage during transit and supplied in an operational state. In addition to supply, we would help customers to choose the correct grinder depending on the power rating, disc size, material type and working environment.

UltraTouch Angle Grinder – Technical Specifications

| UltraTouch Angle Grinder – Technical Specifications | |

|---|---|

| Product Name | Angle Grinder |

| Brand | UltraTouch |

| Voltage / Frequency | 220 V / 50 Hz |

| Input Power | 1050 W |

| No Load Speed | 11,000 RPM |

| Wheel Diameter | 100 mm |

| Spindle Thread | M10 |

| Switch Type | Slide Switch |

| Body Material | High-Grade Plastic |

| Motor Type | Heavy-Duty Copper Motor |

| Insulation Class | Double Insulation |

| Usage Type | Industrial / Professional |

| Application | Cutting, Grinding, Polishing |

| Compatible Accessories | Grinding Wheel, Cutting Wheel, Flap Wheel |

| Country of Origin | India |

Angle Grinder Dealers in Bihar : Nationwide Access and Support

We are a trusted Angle Grinder Dealers in Bihar, Dealers are guided to perceive various user requirements- metal fabricators and contractors to a general maintenance team.

They assist their customers in selecting the appropriate angle grinder that suits them to cut metals, grind surfaces, polish stone, or finish preparation. Our dealer network can guarantee confidence with every purchase stage through warranty system, access to spare parts, and technical advice.

Angle Grinder Wholesalers in Bihar - Bulk Supply and Business Development

We are well-established Angle Grinder Wholesalers in Bihar in order to help with the bulk orders of the retailers and industrial purchasers. Our wholesale clients will enjoy continuous stock, favourable prices, and effective logistics.

The process of ordering has been streamlined, the packaging is secure and the dispatch is carried out at the right time to enable wholesalers to satisfy market demand without short supply. Such close cooperation enhances the penetration of products and business development in the long-term in the power tools industry.

Applications of the Angle Grinders - One Tool, Multiple Uses

The angle grinders have wide applications and can be used in industries in different ways, which include:

- Sawing metal sheets, metal pipes and metal rods.

- Welding of weld joints and rough edges.

- Eliminating rust, paint, and coating.

- Finishing metal and stone surfaces.

- Preparation of surface prior to painting/finishing.

They are highly applied in fabrication workplaces, construction works, automotive repair workshops, stone masons, and residential building works.

Why Our Angle Grinders- Performance you can Trust

Our angle grinders are meant to provide the best cutting and grinding smoothness even in the toughest conditions. The stability in the speed control and minimization of the vibration maintains accuracy and uniform production over the prolonged working hours.

The weight is evenly distributed, there are ergonomic handles, and balancing measures against vibration, which contribute to a decrease in the fatigue of operators. The spindle locks and protective guards are added safety factors that can give the user extra control and safety during use.

Our grinders are available in different power ratings and disc sizes so that they can be used in both light finishing and aggressive material removal.

Call us – Your Angle Grinder Partner in Bihar

Quality is our priority. We work with reliable manufacturers, suppliers, dealers and wholesalers to provide angle grinders designed on a durable, safe, and efficient basis.

Get in touch with us today and discuss all our models of angle grinders. Our team will assist you in making the right choice of tool to enhance surface finish, minimize job time as well as maximize productivity.

Improve the performance of your power tools.

An angle grinder is a United States version of a hand tool that may be in one's collection which can be used to occupying the below-listed operations, such as cutting, grinding, polishing, sanding, and finishing, on a wide range of materials such as metal, stone, concrete, tiles, and masonry. In short, it can be said that this tool is a great helper in the manufacturing, building, workshops, and maintenance fields.

The typical disc sizes are 4 inches, 4.5 inches, 5 inches, and 7 inches. The main range of the small discs is to achieve light work and high accuracy, and on the other hand, the big discs are great for heavy cutting and grinding. The size of a disc is always the size that matches the device's specifications.

It is always required to wear protective clothing, where the main articles of clothing should be safety glasses, gloves, and earplugs. Make sure that the shield is properly installed, the correct disc is used for the work, and that there is not too much pressure. Tool and disc inspection should be done regularly to keep the accident rate low.