Grinding Wheel Manufacturers in Patna

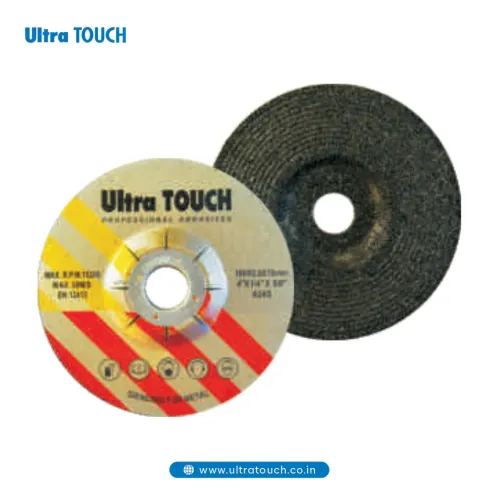

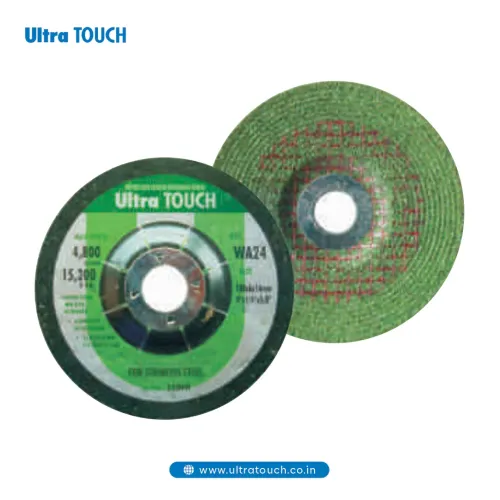

Grinding wheels are used to remove materials, finish surfaces and grind to an accurate surface finish in all types of workshops and industrial applications. Our grinding wheels are manufactured for a smooth cut, stable operation and extended life, even under the most demanding working conditions. With the best quality abrasives and strong bonding materials, our grinding wheels provide controlled grinding with the least amount of vibration, giving you consistent results from one wheel to the next.

Every single grinding wheel that we manufacture is precision balanced for stable rotation and noise reduction, which allows operators greater comfort during use. Due to their rugged design, our grinding wheels can be used on handheld grinders or mounted on machines. Designed to withstand high temperatures, heavy loads and high-speed running, our grinding wheels retain their profile and cutting efficiency for the duration of their useful life.

As a reliable Grinding Wheel Manufacturers in Patna we put a high priority on premium quality, longtime durability and operator safety.

We have well established manufacturing methods and raw materials that have been carefully used in producing our grinding wheels so that they perform uniformly and hence make a reliable investment in workshop, fabrication unit and industrial setup.

Grinding Wheel Suppliers in Patna : Regular Quality Supply.

Being a reliable Grinding Wheel Suppliers in Patna, we serve the needs of small and big-time clients with the constant and steady provision of grinding wheels. We have a good distribution channel that allows us to have stable supply and secure packaging free of damages.

In addition to supply, we will help the customers to make the appropriate choice of grinding wheel according to the type of material, hardness, grinding purpose and compatibility of the machine. We deliver in time with competitive prices either by bulk quantity or standard sizes.

We have been able to become a reliable supplier in many sectors due to our emphasis on long-term relationship and constant service.

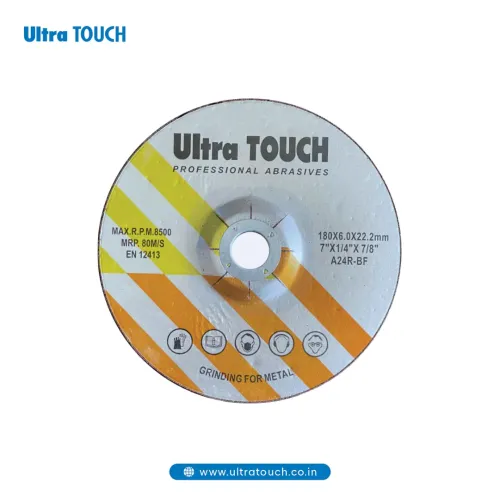

| TECHNICAL SPECIFICATIONS | |

|---|---|

| Parameter | Details |

| Product Name | Grinding Wheel |

| Brand | Ultra Touch |

| Voltage / Frequency | 220 V / 50 Hz |

| Input Power | 1050 W |

| No Load Speed | 11,000 RPM |

| Wheel Diameter | 100 mm |

| Spindle Thread | M10 |

| Switch Type | Slide Switch |

| Body Material | High-Grade Plastic |

| Motor Type | Heavy-Duty Copper Motor |

| Insulation Class | Double Insulation |

| Usage Type | Industrial / Professional |

| Application | Cutting, Grinding, Polishing |

| Compatible Accessories | Grinding Wheel, Cutting Wheel, Flap Wheel |

| Country of Origin | India |

Grinding Wheel Dealers in Patna : Local Support

Authorized Grinding Wheel Dealers in Patna working with us to make sure that there is easy access to real products and provides professional advice. We have a dealer network that assists our customers in selecting the appropriate grinding wheels to be used in the process of metal grinding, surface finishing, deburring, and sharpening.

Buyers can be sure that the products are original and that the dealers will provide proper use of the product and that they are available promptly. The dealers also offer good after sales service to ensure that the customers enjoy safe and efficient operations of grinding. This large local representation enables us to react efficiently to the needs of customers.

Grinding Wheel Wholesalers in Patna : Bulk and Industrial Supply

We are reliable Grinding Wheel Wholesalers in Patna, where we assist the retailers, distributors and industrial purchasers to obtain grinding wheels in bulk without supply failures.

Our warehouse and distribution system promotes effective inventory, low prices, and reliable logistics. This makes the supply chain strong and it has the effect of assuring the availability of grinding wheels wherever they are needed.

Applications of Grinding Wheel

The Grinding Wheels are very common in many industries undertaking activities like:

- Roughening metal surfaces with a smooth finish.

- Eliminating unnecessary material in joints that have been welded.

- Preparation of cutting tools and machine parts.

- Cleaning grooves and polishing uneven edges.

- Prep of the surface prior to painting or coating.

They are widely applied in metal manufacturing facilities, fabrication facilities, car repair facilities, construction facilities, and in maintenance.

Reasons to Choose Our Grinding Wheel

Our Grinding Wheel is made to provide high quality finished surfaces with repeatable and consistent finishes over a long period. Less vibration enhances precision and control by the operator even when it is in heavy-duty use.

High bonding, equal construction provide the features of safety, productivity, and wheel life. Our grinding wheels are compatible with the standard angle grinders and grinding machines and can be easily installed and put to commission without hassles.

We have an effective supplier, dealer, and wholesale network to provide reliable availability and professional assistance whenever they are required.

Get in Touch - Your Grinding Wheel Partner in Patna

We can assist you in choosing the most appropriate grinding wheel that will suit your application. In case you desire an improved surface finish and a shorter time of material removal, then call us now and our team will help you to get to the proper solution.

Place a call and order products in bulk orders.

Consistent grinding solutions which are more hardworking and endurable.

Connect with us now to make your efforts better.

Lower grit takes off stuff quickly but if you want it smooth, go high. Pick what fits how you need it done.

The reason for the very fast wear is that too much pressure has been used or that the wheel is not suitable for the material to be ground. Only make the wheel work and be sure that it is the right one for the job.

A wheel that is perfect for steel may not be capable of cutting stone or softer metals. The right wheel for each material will bring you better results, and the tool will remain safe.